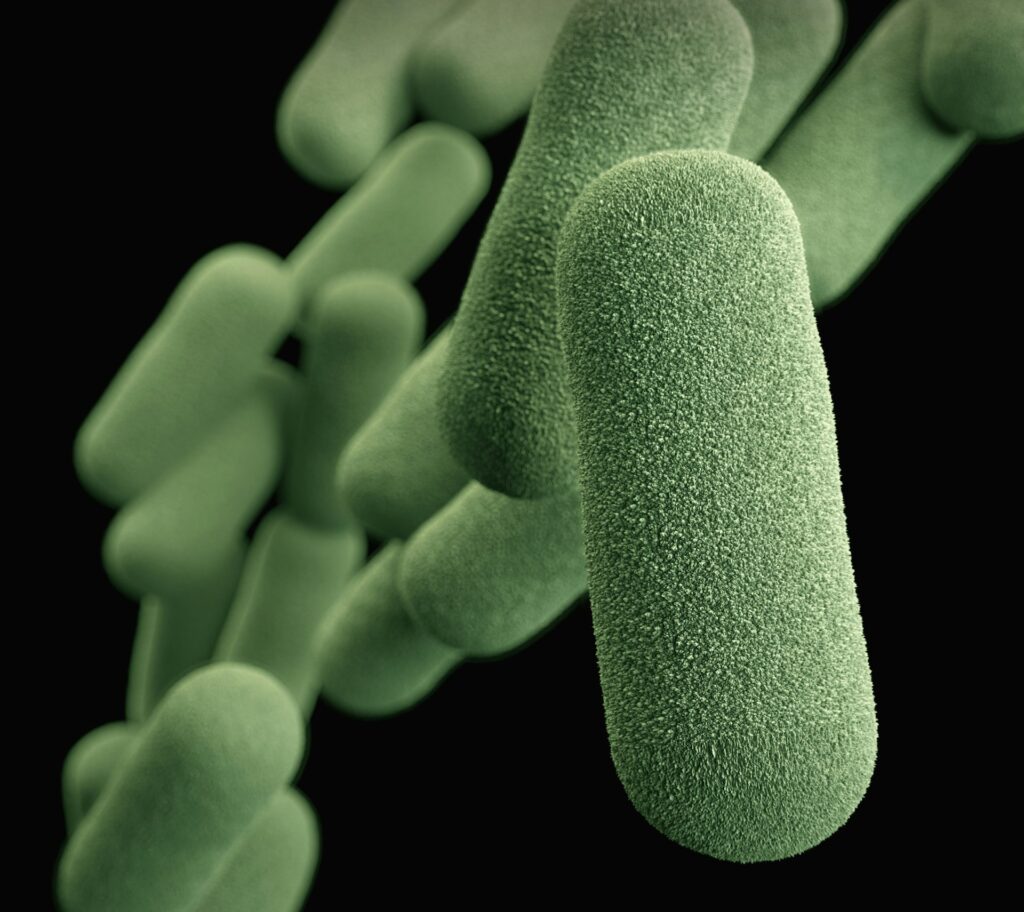

Listeria

Listeria In the past decade, a foodborne pathogen called Listeria monocytogenes has been linked to multiple foodborne disease outbreaks that have been connected to ready-to-eat foods like hot dogs, luncheon meats, cold meats, fermented and dry sausages and other deli-style meat and poultry. Listeria monocytogenes can live in the intestines of animals without causing illness. This could lead to the spread of bacteria to dairy and meat products. When food products are prepared for consumption through cooking or other heating techniques like pasteurization, listeria is eliminated. However, there is a chance that ready-to-eat food could get tainted during preparation, thus posing a risk. Therefore, those who are more vulnerable to the potentially fatal consequences of a Listeria infection, such as expectant mothers and those with compromised immune systems—should take particular precautions. If ready-to-eat food is heated to a scorching temperature at home, Listeria monocytogenes is eliminated.

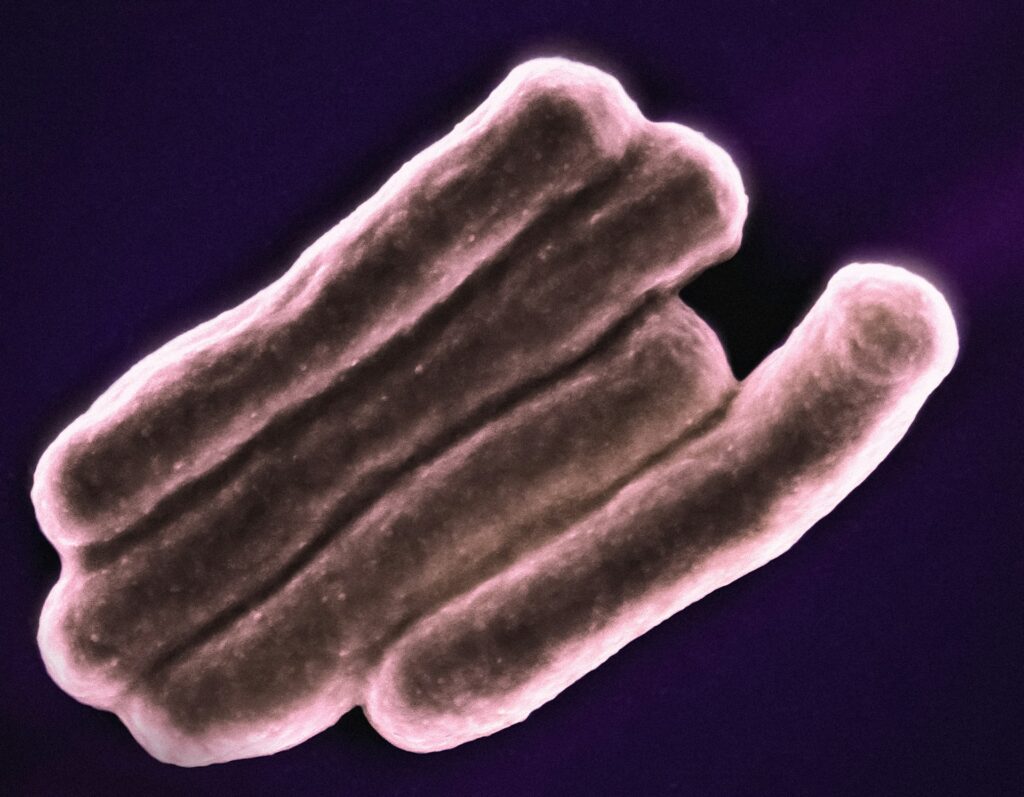

Bacillus cereus

Bacillus cereus Bacillus cereus (B. cereus) is a bacterium frequently present in the environment, existing as spores. Food contamination typically occurs from the soil, air, or water. Rice poses a significant food safety risk because of B. cereus. Raw rice may be contaminated with B. cereus spores that can survive storage. Once the rice is cooked, these spores can germinate and proliferate. To minimize your risk, consume rice immediately after cooking, or keep it at a temperature above 60°C and promptly refrigerate any leftovers. Additionally, when reheating food, ensure that it reaches a minimum temperature of 74°C

Salmonella

Salmonella Salmonella is a highly contagious group of bacteria that produces a foodborne illness called salmonellosis. The bacteria are commonly found in the intestines of healthy animals such as chickens, dogs, cats, and turtles. It spreads to humans by direct contact with animals that carry salmonella bacteria and through consuming contaminated foods. The most common symptoms are diarrhoea, abdominal cramps and fever. Common causes of salmonella infection include: Consuming raw or undercooked meat, poultry or egg products Not washing fruits and vegetables before consuming them Cross contamination from raw to cooked or ready to eat foods Improper hand washing after using the restroom, before and during food preparation, after handling raw food and refuse Remember: Good personal hygiene and good food hygiene are essential in preventing foodborne illness or reducing the risk posed by contaminated food. Wash your hands before eating meals and after playing with animals.

About Mold

About Mold Have you ever gone to your refrigerator for a delicious snack only to find mold has made its home on your fruit or vegetable? Molds have been around for over three million years, so the likelihood we’ll eliminate their presence is slim. Some molds perform valuable functions in our lives. For example, they age, and flavour cheeses and they are used in bread making, fermenting liquor, producing soy sauce, producing penicillin, and manufacturing citric acid used to flavour soft drinks.

About Yeast

About Yeast Yeast is a living single-celled fungus, belongs to the kingdom Fungi, that is used in both bread and beer making. The species of yeast used in food is called Saccharomyces cerevisiae, a Latin name that means “sugar fungus.” The organism is very common all around you, in the air and on the skin of fruits. Although these organisms are often thought to be detrimental to human health, many of them actually exist in the foods you enjoy, such as bread, malt drinks etc. Yeast is a common fungus found both inside and outside the body. The body, however, is equipped to maintain a healthy balance of both bacteria and fungus. Benefits derived from yeast Leavened bread contains yeast, which is a common fungus both inside and outside the body, as well as an effective organism for making bread rise. Yeast functions by metabolizing the simple sugars of the dough. The byproduct of the metabolic activity is carbon dioxide and alcohol, which in turn causes the bread to rise. That is the reason why yeast is vital in bread baking, brewing and winemaking. This process is referred to as fermentation, meaning the chemical breakdown of a substance by micro-organism such as yeast. Yeast plays such a crucial role in winemaking that without its presence, you cannot turn grape juice into wine. The juice simply will not ferment without the help of yeast. Bread baking, beer brewing and winemaking is a beautiful combination of art, science, magic and involves loads of patience.

Information You Need To Know About Foods In Cans

Information you need about foods in cans Foods can be preserved for extended periods of time by canning them and sealing them in airtight jars. The late 18th century saw the development of canning as a means of giving sailors and soldiers a reliable supply of food during times of conflict. Each product will require a somewhat different canning procedure, but there are three basic phases. Processing food can be cooked, sliced, chopped, pitted, or shelled. Sealing (Closing). Cans are used to seal the processed food. Heating up. To eradicate dangerous microorganisms and stop spoiling, cans are heated. This makes food safe to eat for up to three years on the shelf. Fruits, vegetables, beans, soups, meats, and seafood are among the common foods that are canned. The food is heated to a safe temperature during the canning process, which also creates a vacuum and keeps bacteria out of the food. The food is heated to a safe temperature during the canning process, which also creates a vacuum and kill the bacteria which may be present in the process. This produces an environment that makes it very unlikely for dangerous bacteria to proliferate unless the cans get damaged.

Macronutrients – Protein

Macronutrients – Protein Macro nutrients are defined as the substances or components that are needed by the body to serve as nourishment to facilitate cell growth, repair, and overall maintenance of life. The word macro means large, hence macronutrients collectively mean nourishment needed in large quantities. There are three main macronutrients, namely, carbohydrates, proteins, and fats. They are all required by the body depending on the age, gender, height, health, and lifestyle of an individual. The macronutrient category of interest today is proteins. Proteins are beneficial to human health as they are responsible for cell structure, function, and repair. This includes tissue and organ regulation. At molecular level, proteins are made up of small nitrogen containing units known as amino acids. There are 20 different types of amino acids which form complex linkages/chains to form proteins. Out of the 20 protein types, 9 are essential proteins which means they cannot be made by our bodies compared to the rest which are known as non-essential. Essential proteins cannot be made by our bodies as the non-essential proteins. Hence, it is crucial to know which are crucial to supplement in our diets. Here are more reasons to consume proteins: Satiety – proteins give the feeling of fullness. Hence, they can avoid cravings by managing hunger. This is beneficial to weight loss and control. Building blocks – proteins can help our bodies with repair and rebuild muscles, skin, hair, nails. Immune response enhancement – important components of the immune system is made up of proteins such as antibodies and lymphocytes. These act collectively to alert the body of disease-causing bacteria or viruses. Reduce the risk of diabetes – it is reported that there is a correlation between lifestyle disease and the protein deficiency to the risks of diabetes. Protein facilitates satiety and maintains the blood sugar levels. When it lacks, insulant resistant individuals may experience irregular blood sugar patterns after meals. Protein consumption has decreased as some of the protein sources are costly or cause significant environmental impact. Here 5 sustainable sources protein includes eggs, chicken, tofu, milk, and beans. If unsure a visit to a nutritionist may help. Sources https://youtu.be/smPR215SRzM https://medlineplus.gov/genetics/understanding/howgeneswork/protein/ 6 Health Benefits of Eating More Protein | The Active Times https://www.eufic.org/en/whats-in-food/article/what-are-proteins-and-what-is-their-function-in-the-body 9 Health Benefits of Eating More Protein – Nutrition Advance https://youtu.be/_N1xX49AqwQ Protein Foods | MyPlate https://www.everydayhealth.com/diet-nutrition/7-foods-fight-back-immune-system-boosters/ https://www.healthshots.com/preventive-care/self-care/can-adequate-protein-consumption-help-prevent-diabetes/ https://medcraveonline.com/JCCR/lifestyle-diseases-consequences-characteristics-causes-and-control.html

What are carbohydrates/ Carbs?

What are carbohydrates/ Carbs? Carbohydrates (also known as Carbs in short) are organic compounds of carbon and oxygen, that are digested, absorbed, and broken down in tissues into water and carbon dioxide. They provide your body with energy to function properly and stay healthy. Carbs consist of fibers, sugars, and starches. When you take in carbohydrates your body breaks down the nutrients to glucose for energy. It is important to know how Carbs work in your body. The consumption of too many carbohydrates rich foods may be detrimental to your health, such as excess fat storage may cause obesity and high blood pressure. When thinking of what Carbs are beneficial to your diet, consider complex Carbs. What is the difference between simple carbs and complex carbs? Simple carbs– Well, sugars are simple carbs that can be digested much more quickly than complex carbs. These Simple carbs are converted into glucose extremely fast and making your blood sugar levels high. Easy way to get anergy right? When blood sugars are high, then drop lower than they are supposed to, this leaves you tired, inactive, and the rest is stored as fats. Examples of foods rich in simple carbs are sodas, ice-cream, chocolate, white bread, white pasta, cakes, pastries, packaged cereals, and other packaged baked goods. Complex carbs- There are two types of complex carbohydrates which are starch and fiber. Complex carbs have more nutrients compared to simple carbs, since they contain more fiber and are digested slowly. It also makes complex carbohydrates more filling which indicates that they are a better option to control weight. Complex carbs are converted to glucose for energy and help your body fight common health issues such as high cholesterol, high or low blood sugar levels, and various heart diseases. Major sources of dietary fiber – Vegetables, nuts, fruits, whole grains, and Beans Major sources of high starch -cereals, Wheat bread, corn, and oats. Too much of a good thing can also be a bad thing, right? That’s why you should be able to limit your daily intake of both simple and complex carbs. Again, a balanced diet is the best diet. Here is an example of what to substitute (sub) in your diet Fruits – sub for candy Nuts – sub for processed snacks Asiago, mozzarella, provolone – sub for processed cheeses Shellfish – sub for any main course Cauliflower crust – sub for pizza dough and other grains Dark chocolate – sub for milk chocolate and other sweets You can also track your carb intake by reading nutritional labels and doing research on how your body type reacts and burns carbohydrates.

Etosha Fishing Case Study

In celebration of seven (7) years in business, Iyalago Food Assurance Consultants (IFAC) is delighted to share its remarkable achievements in the field of Food Safety and Quality Assurance within the Namibian Food Industry. Among our proudest accomplishments is the success story of Etosha Fishing, one of our earliest clients. Iyalago Food Assurance Consultants (IFAC) has diligently supported Etosha Fishing in achieving excellence, ensuring that their canned products meet the stringent quality standards demanded by both local and international markets. Through rigorous assessments, strategic guidance, and collaborative efforts, we have contributed to Etosha Fishing’s growth and reputation as a reliable supplier of safe and high-quality canned seafood. Stay tuned as we delve into more inspiring stories and continue our commitment to elevating food safety practices in Namibia and beyond! Background Etosha Fishing, the last remaining cannery in Namibia situated in Walvis Bay, has a rich history dating back to its refurbishment in 1995. Despite facing challenges such as limited fish resources in the country, Etosha Fishing has maintained its position as a leader in the industry, boasting high-tech equipment and a commitment to delivering high-quality canned food products. In the 2010s, Etosha took on the responsibility of canning for various renowned brands, including their own Efuta brand, necessitating a revamp of their integrated food safety, quality assurance, and environmental systems to meet world-class standards. With the support of Iyalago Food Assurance Consultants (IFAC), Etosha embarked on a journey to enhance its food safety and quality practices. Problem Definition Etosha Fishing recognized the need to update its existing food safety, quality assurance, and environmental systems to align with industry, regulatory, and customer requirements. Despite its advanced equipment and commitment to quality, the company faced challenges in ensuring standardization of work among its quality assurance team and providing sufficient training on food safety in canning operations to its ground team. Solutions Implemented IFAC collaborated closely with Etosha Fishing to implement a comprehensive strategy aimed at optimizing food safety and quality practices. The solutions included: Standard Operating Procedures Optimization: IFAC worked with Etosha Fishing to review and optimize their standard operating procedures (SOPs) to ensure standardization of work among the quality assurance and production team. This involved streamlining processes, clarifying roles and responsibilities, and incorporating best practices in food safety and quality assurance. Team Empowerment through Training: IFAC conducted tailored training programs for Etosha Fishing’s ground team on food safety in canning operations. These training sessions focused on educating employees about the importance of food safety, specialized canning procedures, and compliance with industry standards. By equipping inhouse trainers with knowledge and skills, conducting the team at Etosha Fishing was able to enhance its food safety culture and ensure adherence to Food safety laws. First Party Audits (Internal): IFAC assisted Etosha Fishing in conducting first-party audits to verify the effectiveness of their food safety and quality management systems. These audits provided valuable insights into areas for improvement and helped the company identify and address any deficiencies proactively. Results The collaboration between Etosha Fishing and IFAC yielded significant improvements in food safety and quality practices, positioning the company as a leader in the industry. The key results achieved include: Here is feedback from the Etosha fishing team on the value added to their Food safety and quality management system. Linekela Kapundja, Quality Manager says the following at a strategic level, Working with you [IFAC] has improved or quality management system for the better. The value that we got from the training material you developed for our internal training manuals is excellent. While, Irene Nambahu, Quality Superintendent says the following at operational level, As our consultant internal auditors; we can attest that with your valuable input our food safety system (especially documentation) has improved greatly. The number of HACCP audit findings has reduced since we started making use of your services since 2018. [There is] great effort put into the presentations of your training. Your diversity is a bonus to the food industry, [your team] is very knowledgeable in a number of systems and your knowledge and training is not limited to the fishing industry. Your availability /open door /approachable and flexibility to suit customer needs [is an added benefit]. Conclusion Through the support of IFAC, Etosha Fishing successfully transformed its food safety and quality practices, reaffirming its position as the last remaining cannery in Namibia. By optimizing standard operating procedures, empowering the team through training, and conducting internal audits, Etosha Fishing demonstrated its commitment to excellence in food safety and quality assurance. This collaborative effort has not only ensured the company’s continued success but also contributed to the overall advancement of food safety standards in the industry.

Seawork Fish Processors Case Study

Background Seawork Fish Processors is a leading fish processing company known for its high-quality seafood products. With a growing demand for their products both locally and internationally, the company recognized the need to enhance their food safety standards to meet customer requirements and remain competitive in the market. In response to customer demands and industry trends, Seawork decided to pursue IFS Food Certification, a GFSI-benchmarked and globally recognized standard for food safety and quality management systems. Problem Definition The primary challenge faced by Seawork was to implement the IFS Food Certification system efficiently and effectively within their fish processing facility. This involved understanding the requirements of the certification, optimizing existing processes, acquiring necessary knowledge and skills, and streamlining operations to meet the rigorous standards set forth by IFS Food certification scheme. Solutions Implemented Seawork embarked on a comprehensive journey to address the challenges posed by implementing the IFS Food Certification system. The solutions implemented included: System Optimization: Seawork conducted a thorough assessment of their existing processes and identified areas that needed improvement to align with IFS Food standards. This involved updating facilities, equipment, implementing new protocols, and revising existing procedures to enhance food safety and quality. Knowledge Acquisition: To ensure compliance with IFS Food requirements, Seawork invested in training and development programs for their employees. This included educating staff on food safety protocols, hygiene practices, and quality management principles. Streamlining Processes: Seawork streamlined their operations to optimize efficiency and effectiveness in meeting IFS Food standards. This involved reorganizing workflows, implementing standardized procedures, and adopting technology solutions to automate tasks and minimize errors. IFAC’s Role Seawork enlisted the expertise of Iyalago Food Assurance Consultants (IFAC) to guide them through the process of implementing the IFS Food documentation system. IFAC played a crucial role in planning and collaborating on the project, offering specialized knowledge and support at every stage. Their assistance included: Document Review: IFAC conducted a comprehensive review of Seawork’s existing documentation and processes to identify gaps and areas for improvement in relation to IFS Food requirements. Compilation Assistance: IFAC assisted the dedicated Seawork team in compiling the necessary documentation and paperwork required for the certification process. This involved ensuring that all documentation met the stringent requirements set forth by IFS and fishing industry best practices. Training Plan Creation: IFAC worked closely with Seawork to develop a customized training plan for their employees. This plan included both classroom-style training sessions and on-the-job coaching to ensure that staff were adequately prepared to implement and maintain the IFS Food Certification system. Effective Internal Audit program: IFAC contributed to effectively training a competent internal audit team responsible for verifying the IFS Food system. Results Through the collaborative efforts of Seawork and IFAC, the company successfully achieved IFS Food Certification for their fish processing facility. The implementation of the certification system not only enhanced food safety and quality standards but also improved operational efficiency and customer satisfaction. Seawork’s commitment to excellence in food safety and quality management has positioned them as a trusted provider of seafood products in the global market. Here is feedback from the Seawork Fish Processors’ team on the value added to their IFS Food system and experience in IFAC training courses: Mariette van Zyl, Quality Assurance Manager The fact that the people [IFAC] assisting with consultation or presenting of the training courses have vast experience in the fishing industry. I have recommended [IFAC] to others. [Please feel free to elaborate more about how we added value to your system and your experience with as] Marchalino Ambrosini, Production Manager In the Food defense and Food fraud training course, I learned the importance of making sure your product is protected and how to do a risk and vulnerability study. Tjaard De Smit, Technical Manager As part of the HACCP team, I [value] and learned the importance of HACCP to export our final product. Josia Halwoodi, Internal Auditor I found the training quite informative and relevant to our operations. I learnt a lot from the training. My great take away from the training was the turtle diagram under the audit execution [process approach]. The diagram is easy to follow, and it is such a good tool for internal auditors. In conclusion, Seawork’s journey to implement the IFS Food Certification system with the assistance of IFAC demonstrates the importance of proactive measures in meeting customer requirements and industry standards. Through careful planning, optimization, and expert guidance, Seawork was able to achieve their goal of enhancing food safety and quality while maintaining competitiveness in the market.